| HAPTIVITY® is Kyocera's virtual reality technology that allows the simulation of a mechanical button and further haptic effects on any surface. A key distinguishing feature is HAPTIVITY's® ability to provide dual feedback - a vibration on the press and a second vibration on the release. This replicates the tactile experience of a mechanical button more closely than single-vibration systems. |  |

|

Target Markets

Automotive The automotive market has been steadily moving away from mechanical switches and buttons for many operations in the interior of automobiles in favor of larger displays with icons and a touchscreen for users to select the appropriate function. But, what was once a "fool proof" sensation of pressing a button or flipping a switch has now become a possible distraction for the driver by requiring input to be verified through other senses. The auto industry's goal is to make the vehicle interior more seamless and homogenous but maintain the feedback of buttons and switches the driver has become accustomed to and expects. So far, haptic feedback systems used in the automotive market are all based on magnetic solutions that have respective drawbacks like space required, slow response and limited functionality.

Industrial Similar to the automotive market, the industrial market is also looking to move away from mechanical buttons and create a more seamless and homogeneous interface for the end user. In some applications, industrial customers have started to move away from mechanical buttons to save cost and space by replacing the mechanical buttons with virtual buttons embedded into the touch sensor or the use of icons on the display, but the desire to have the sensation of pressing the button still remains as a priority for the end users. The implementation of haptics into industrial displays is challenging since there are specific requirements regarding dust and waterpoofness.

Key Features of Kyocera's HAPTIVITY® Technology

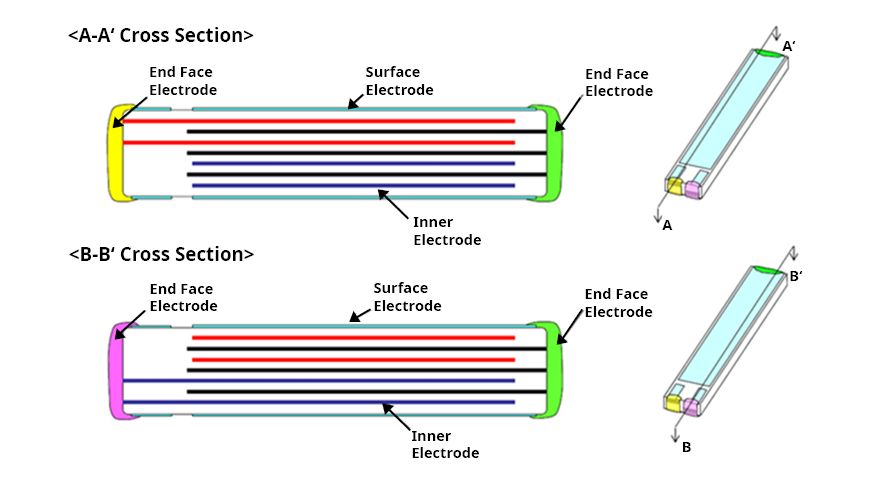

Scheme of a Multi-layer Piezo

* The number of layer lamination is shown as "8 layers," which is a typical example. * Common structure for uni-morph and bi-morph, therefore A-A' and B-B' are different.

HAPTIVITY® Principle In order to simulate a mechanical button it is not sufficient to apply just a vibration to the surface that has been touched from the operator. It is absolutely essential to generate a distinctive surface vibration only after the operator has exceeded a certain pressure threshold – similar to a mechanical button. Therefore, the device must comprise a component that is able to measure the applied pressure. In certain configurations this can be the actuator piezo itself (by utilizing the reverse piezo-electric effect of the actuator functionality), but in general it should be a separate pressure sensing component. After a pressure threshold has been exceeded (which is detected from the implemented controller), a single sine half wave of ~30V is applied to the actuator piezos. According to the piezo-electric effect, the piezo(s) geometry will change. With a suitable mechanical device this piezo shrinkage is converted into a lateral movement which is coupled into the touch surface.

How to implement HAPTIVITY® into Your Device?

Key Points

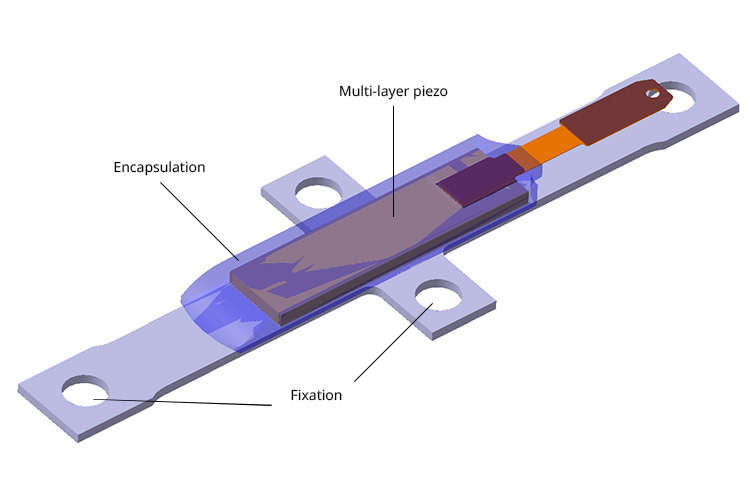

Mechanical Integration The actuator / haptic block (schematically illustrated below, length about 6 cm) has to be attached tightly onto the device which has to be vibrated - ideally on the rear side - by attaching with screws. The mounting position does not necessarily have to be centered at the device.

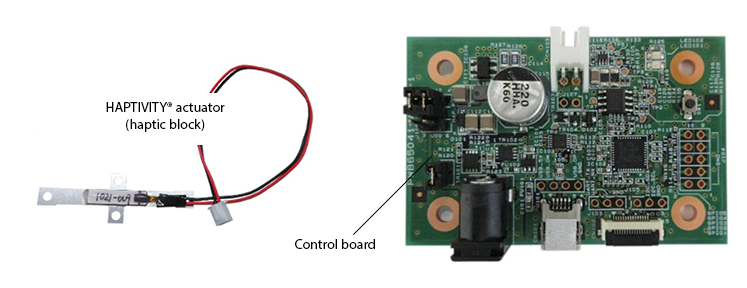

Development Kit For an individual investigation and testing, Kyocera provides a Development Kit, containing actuators as well as a complete driving system with different driving features.

Please contact us for additional information. |